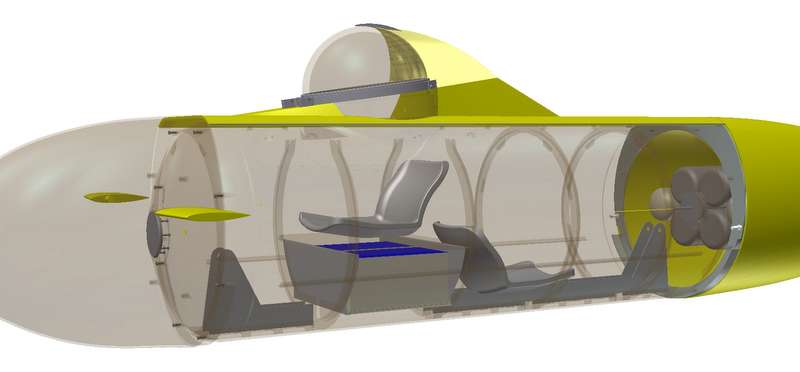

will probably be the smallest autonomous long range submarine ever built and the first human powered one.

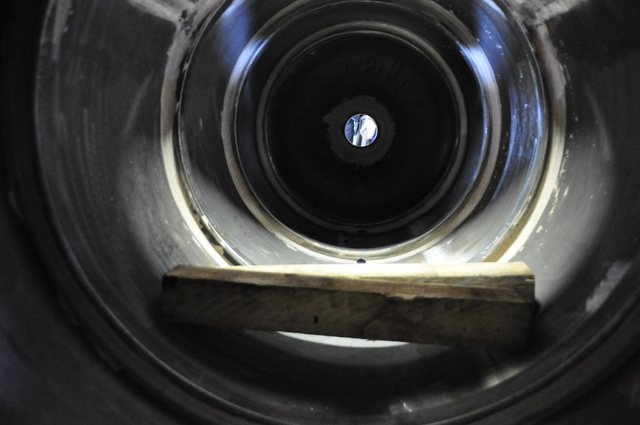

Unlike scuba divers, we will breathe recycled air at atmospheric pressure inside the submarine. This will be achieved thanks to a 1 cm thick steel hull that will protect us from the external pressures with a factor of safety of 3.

To give an idea of the tremendous forces involved, opening the hatch at the maximum trip depth of -120m would be as easy as lifting a heavy road lorry.

This is also a challenge and a specificity of our project. Even after training, our legs will not deliver the power to cruise at high average speeds. So a lot of effort has been put towards drag reduction, via notably a streamlined outer hull in fiber glass composite. Design mistakes will be paid in sweat!

for air, propulsion, navigation, data acquisition for two co-pilots over a week. Featuring all this in such a small living space is one project in itself.

has been and will be our foremost priority. The submarine design and construction will meet or exceed internationally recognized standards for manned submersibles, under the supervision of professionals. Key elements will be tested before the expedition, like the hull which is to be tested unmanned at twice the expected water depth. During the expedition a surface vessel will follow the submarine to be there in case of emergency (it will also record the submarine's position accurately for data exploitation).